Solution

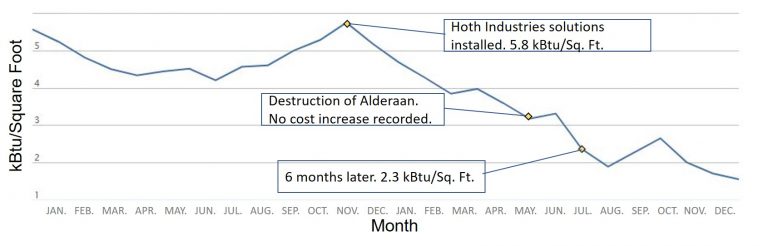

With construction of the Death Star taking significantly longer than expected, Death Star leadership saw an opportunity to optimize their energy performance, but were not confident where to begin. After working with EnergyPrint to identify possible avenues of improvement, the Empire brought in outside contractor Hoth Industries to update their antiquated ion energy systems with a new hypermatter reactor. Additionally, they were able to install more efficient carbonite chillers for temperature control and smart gravity and atmosphere systems throughout the facility to allow for remote monitoring and control, as well as advanced scheduling and setback capabilities.

“The Emperor will be most pleased with our progress,” says Grand Moff Tarkin, the Death Star’s commanding officer. “Working with EnergyPrint has been a success on almost all counts. They were even able to break down demand charges for us. By planning our planetary destruction during non-peak hours, we’re able to save a substantial amount of cost while achieving the same amount of fear that will keep the local planetary systems in line.”

With EnergyPrint’s Utility Dashboard as a guide, the Death Star team benchmarked the station’s performance to monitor its monthly progress and validate savings results. They were even able to increase their ENERGY STAR SYSTEM® score by over 25 points. The success of the Death Star pilot program also indicated potentially trillions more in savings to be earned across the Empire’s portfolio of installations. To begin, the Empire is moving forward with benchmarking the performance of their entire fleet of star destroyers under the supervision of Lord Vader, with plans for additional facilities to follow at a later date.